DELI DANE OLIVE OIL FACTORY

Location: Milas, Kemikler

Project type: Industrial

Project year: 2025

Construction area: 1.200 m²

Land area: 12.000 m²

Status: Completed

Project team:

Kemal Bal, Nil Bıçak, Erol Kalmaz, Büşra Yavuz

Soil and Olive

As the Aegean wind drifts over sun-baked lands, it gently rustles the leaves of ancient olive trees. These trees do more than bear fruit; they carry a culture, a memory, a character. The olive oil that Homer called the “liquid gold” is not merely a food here, but a way of life. The olive, bestowed upon the earth through Athena’s wisdom, shapes the identity of the Aegean. In this geography, olive groves have taken root not only in the soil, but in time itself.

Delidane walks precisely in the footsteps of this deep-rooted culture. Its name comes from the wild olive — delice — and the care given to each dane (olive fruit). The respect for the olive extends beyond the production process; it also inspires the architectural composition of the building that processes it.

Site Selection and Design Intent

Delidane Olive Oil Facility is located in Kemikler Village of Milas, surrounded by olive trees and close to Bodrum–Milas Airport. The aim is to create a small-scale yet high-quality production area where the company can process its own olives.

In the initial design phase, a fragmented layout was proposed, comprising a production building, tasting and sales area, and residential units. However, zoning regulations limited construction to a single mass. This constraint led to the creation of a flexible structure capable of accommodating various functions over time.

Relationship with Nature

A key design priority was to preserve the existing olive trees and maintain the natural landscape. Therefore, the building was placed in the relatively treeless north-western corner of the site. A service courtyard was defined in this area to enable vehicle access while minimizing the contact between logistics activities and the landscape.

Considering the topography and natural slope of the terrain, the building was oriented along an east–west axis, facing the lower-level access road. This façade became the most visible face of the structure and the main reference point for visitors.

Architectural Composition and Material Language

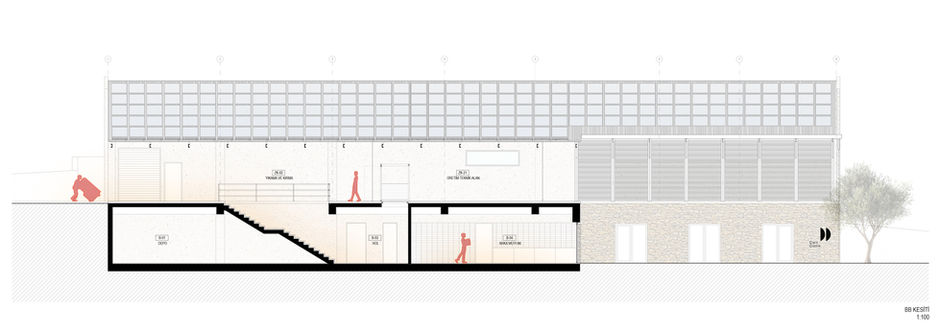

Due to the site’s section, a long and narrow basement level emerged beneath the structure. Rising above a stone plinth that forms this basement, the building is a single-story mass with a floor height of four meters. Its gable roof simplifies the volume while adding spaciousness to the interiors.

To soften the cold, neutral character of an industrial facility, and to balance the southern sunlight while giving the façade architectural refinement, a continuous canopy was designed along the building’s length. Positioned on the road-facing façade, the canopy is supported by columns placed at 2-meter intervals atop the stone base. The broad eave extending outward from these columns has become the defining element of the building’s architectural identity.

Over time, this façade composition has become not only functional but also a visual signature of the structure. The recesses beneath the eaves create depth, allowing natural light to play through layers of shadow. The canopy columns were initially designed in wood, but were later executed in steel to match the roof structure. Bamboo panels were installed between the columns to provide shading and privacy. The combination of stone, steel, and bamboo establishes a delicate balance between traditional and contemporary architecture.

Functional Organization and Production Process

The plan layout was developed in response to the sequence of olive-oil production. The process begins with the reception, washing, and sorting of olives, followed by pressing, filtration, and storage. The olive oil is stored in stainless steel tanks reaching up to 4.5 meters in height, then bottled, packaged, and prepared for distribution. This production cycle is organized in a U-shaped flow within the building, ensuring a controlled movement of materials through the same service courtyard for both entry and exit.

Staff facilities are located at the opposite end of the building. Functional units such as locker rooms, kitchen, and laboratory are designed independently from the production zone, with direct external access provided through the front canopy.

At the rear, a service corridor has been created by taking advantage of the site’s natural slope. Mechanical and technical spaces placed here are both concealed from view and easily accessible for maintenance operations.

Architecture Rooted in the Land

The Delidane Olive Oil Facility embodies an architectural attitude that chooses to coexist with nature rather than compete against it. Every design decision was made with respect for the olive and the soil in which it grows. The strength of stone, the simplicity of steel, and the naturalness of bamboo together create a language that is both timeless and deeply connected to its context.

This building is more than a production facility; it is a narrative that carries the memory of the land. Nestled gently among olive trees, it is a structure that bows with respect — to both the past and the future.